Mikrotek manufactures Tips & Dies to suit any existing crosshead. These tools are made from the best of the materials, hardened, ground and polished. They are precise and longer lasting.

They are made with different materials depending on the application - hardened steel, tungsten carbide and diamond.

Tips and dies are made in different shapes – round, shaped, multiple cores etc.

Maximum care is taken in checking the hardness, accuracy, concentricity and finish.

All the tools are hardened, ground and diamond polished.

They are made to suit Mikrotek crosshead or any other existing crosshead.

While ordering tips and dies,either provide drawing or a used sample.

Choose the size using the following guidelines

Conductor diameter = d

|

1. SOLID WIRE d < 1.8 mm, Nozzle diameter = 1.04 x d d > 1.8 mm, Nozzle diameter = d + 0.11 mm |

|

2. STRANDED WIRE d < 1.8 mm, Nozzle diameter = 1.08 x d d< 1.8 mm, Nozzle Diameter = d + 0.15 mm |

Insulation diameter = D

| Material | Extruder die diameter |

| LDPE HDPE PVC PP |

D D + 10% D + 5% D + 25% |

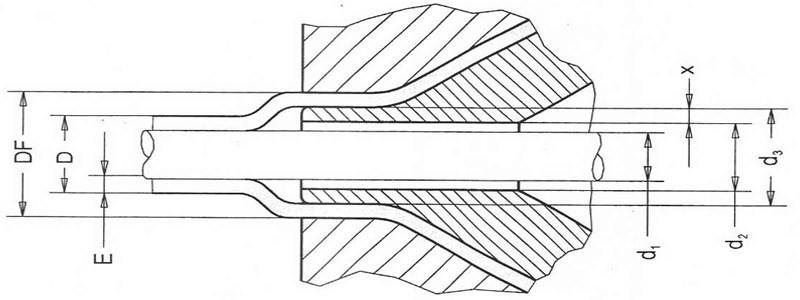

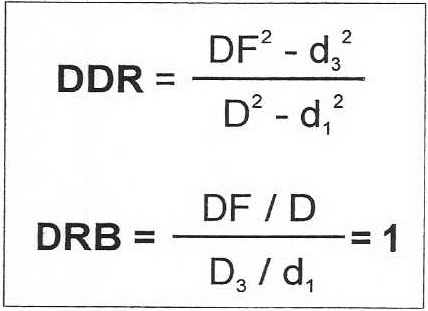

Two main elements are necessary for the calculation of a tubing tools:

DDR=>Draw Down Ration

DRB=>Draw Ratio Balance

The DDR is in correlation with the polymer and the DRB has to be close to 1

We have here:

| DF | => | ∅ Die outlet |

|---|---|---|

| D | => | ∅ Over insulation |

| E | => | Thickness insulation |

| d1 | => | ∅ from the wire |

| d2 | => | ∅ Inside wire guide |

| d3 | => | ∅ Outside wire guide |

| x | => | Thickness wall wire guide |

For the calculation of the tools we are using the two formula above